- 91/92, GALI NO. 2A, RAJINDER NAGAR INDUSTRIAL AREA, MOHAN NAGAR, GHAZIABAD, UTTAR PRADESH - 201007

- info.namanenterprises@gmail.com

- 9871917917, 9910029390

Pad Printind Jig Fixtures

Pad Printing Metal, Acrylic, Nylon or Teflon Jig Fixtures

The Jig fixture is a female cavity of the substrate you want to print on

The Accuracy Of The Fixture Is Very Important. If It Not Accurate The Substrate Is Move While Printing And Cause Miss-printing. A Jig Or Fixture Is Designed And Built To Hold, And Support Component (part) To Ensure That Each Is Printed Within The Specified Limits. Jig Fixtures Can Be Cnc Machined In Acrylic, Teflon Or Make From Epoxy Material.

>> Different Materials - We make Jig fixtures in three types of materials they are Epoxy, Acrylic and Nylon or Teflon. Small single color jobs can be made in Epoxy material while 2 or more color registration jobs are made in Acrylic or Nylon Materials.

>> Cost Effective - Epoxy Jig Fixtures are cost effective as it is manually made Acrylic and Nylon or Teflon Jig are made by CNC Milling Machines therefore they are very accurate but expensive

>> Quick Delivery - Epoxy Jig Fixtures are generally completed with 2-3 working days unless they are complicated while Acrylic or Nylon Jig Fixtures take at least 10 working Days to Complete

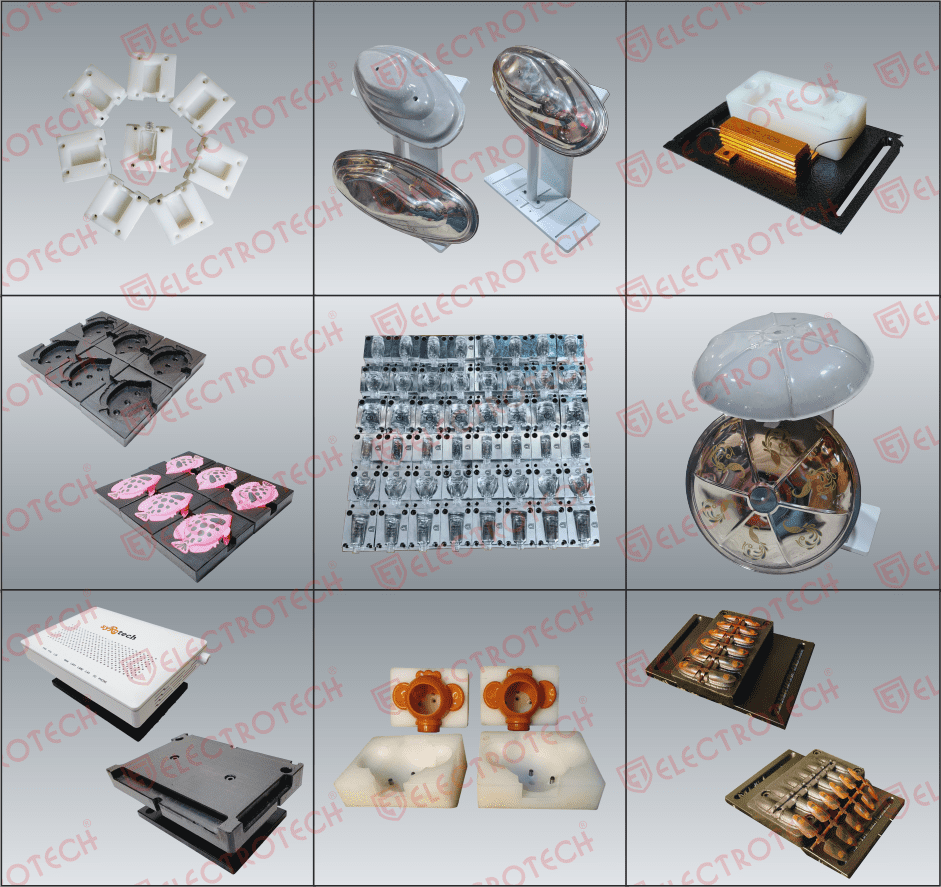

:- Our Different Varieties Of Pad Printing Jig Fixtures

Acrylic Jig Fixtures :-

Acrylic Jig Fixtures are made from Acrylic Sheets. They are Durable and and accurate as fixtures made on CNC Milling Machines. The whole process is computerized therefore very accurate

- :- Accurate CNC Milling

- :- Durable.

- :- Computerized Process.

Nylon or Teflon Jig Fixtures :-

Nylon or Teflon Jig Fixtures are made from respective Sheets. They are Durable and and accurate as fixtures made on CNC Milling Machines. The whole process is computerized therefore very accurate.

- :- Accurate CNC Milling

- :- Durable.

- :- Computerized Process.