- 91/92, GALI NO. 2A, RAJINDER NAGAR INDUSTRIAL AREA, MOHAN NAGAR, GHAZIABAD, UTTAR PRADESH - 201007

- info.namanenterprises@gmail.com

- 9871917917, 9910029390

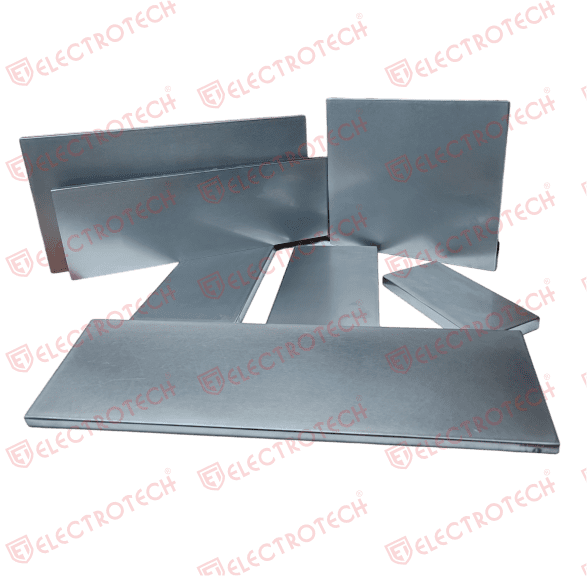

Thick Steel Clichés

The Cliché Or Steel Plate Is The Carrier Of The Print That Will Be Required On The Product Or Component.

Traditionally the plates are generally of thick steel material which is made by a very special process of hardening and etched by chemical milling process. As clichés or plates for pad printing have very high importance hence selection of proper plates or clichés is extremely critical for quality.

Varying types of clichés are used depending on the desired print quality and quantity. The motif is recessed, etched into or washed out of the cliché. In order to assure smooth fitting and printing, the motif should be at a distance of at least 25 mm (1 inch) from the outer edge, and centered on the plate. In the case of long or fine lines, the motif must be at an angle of approx. 5° to 15° to the blade track in order for the doctor blade not to dip too low and scoop out too much ink.

Numerous trials have shown that an etching depth of 30-35 µm is optimal for pad printing. Since the pad can only transfer a limited quantity of ink, a greater depth is pointless. At an etching depth of 30-35 µm, the pad only picks up an ink film of 12 µm. The rest remains in the depressions of the cliché. Because the ink film consists of approx. 40 % to 60 % thinner, which evaporates during the transfer and drying, the actual thickness of the ink film left on the substrate comes to around 5 µm - 8 µm, in some cases, as little as 2 µm. As an exception to the above statement, very fine fonts are etched at approx. 15 µm, and very large motifs, at approx. 30 µm. For very large surfaces, the dip of the doctor blade can be avoided by additionally copying a fine screen into the motif

Thanks to our many years of experience and process expertise, we know how essential it is for all process components to be in perfect harmony in order to achieve ideal print results. That is why we produce our cliché material ourselves. Through constant optimization and further development of the cliché material, we are able to offer a cliché material optimally matched to the pad printing process for every application

Our Cliché Is Produced From Special Tool-grade, Abrasion-proof Steel

Its area of application is found primarily in the industrial sector. Steel clichés are especially suited to high quantity printing runs and closed ink systems. The quality of these clichés is unequaled. This is evident from their absolute sharpness of contour, multi-stage etching, utilization of screens of all types, very fine surface, low susceptibility to physical damage and consistency in high quantity printing runs. The number of prints which can be achieved using this cliché comes to at least 1,000,000 doctoring operations.

These plates are sized, ground, toughened, lapped, polished and etched. The whole process cycle take about 25 days. Hence standard sizes are mostly in stock and special clichés/ plates need time.

| Steel Type | GCr15 | 2510 (01, CrWMn) | AISI D3 (X210CR12) |

|---|---|---|---|

| Cliché Marks | HR | EN | D3 |

| Rust Resistance Ability | *** | *** | *** |

| Printing Life | ✓✓ | ✓✓✓✓ | ✓✓✓✓✓✓ |

| Heattreatment Hardness | HRC 63+/- |

|---|---|

| Cliché Surface Finish Roughness | Black Surface---Ra0.1 µ m |

| Bright Surface---Ra0.01 µ m | |

| Mirror Surface---Ra0.001 µ m | |

| Cliché Surface Parallel | For Open Type Pad Printers.....500:0.05mm |

| For Cup Type Pad Printers.....500:0.005mm | |

| Cliché Machining Thickness | Common Thickness : 9.5-12mm |

| Special thikcness: 8mm, 9mm, 12mm, 13mm, 15mm, 18mm, 20mm | |

| Other thickness can be customized. | |

| Cliché Plates Common Size | 70x140, 75x150, 75x150, 75x210 100x100, 100x150, |

| 100x200, 100x215, 100x250, 100x400, 100x500, | |

| 100x600, 100x700 150x150, 150x300, 150x350, | |

| 125x225, 85x175, 200x200, 125x300, 180x200, | |

| 70x650, 100x350, 150x500, 200x400, 200x500... | |

| Cliché Machining Size | Any special size clichés can be made to order. |

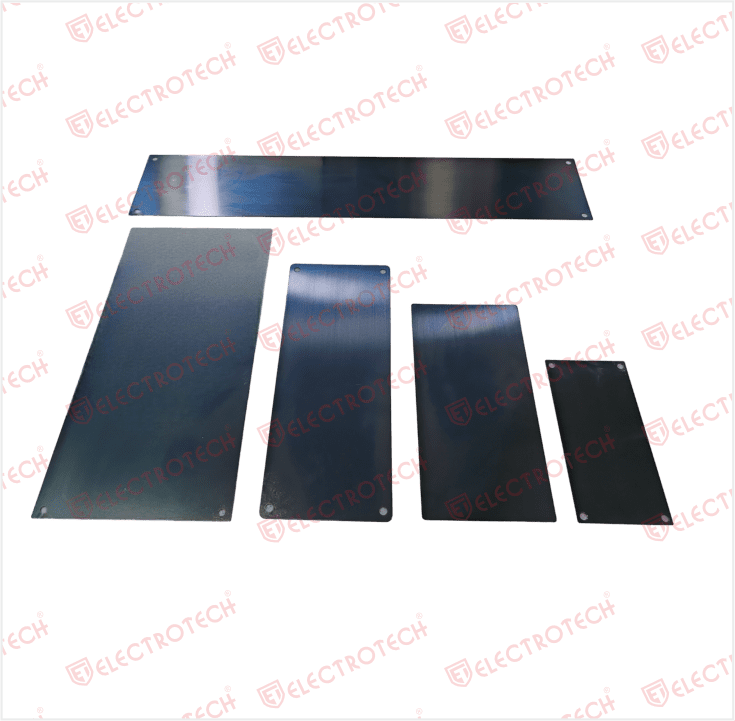

Thin Steel Clichés

In pad printing, thin steel plates are used for small to medium-sized production runs. Thin steel plates are very cost effective, easy to etch and provide good printing results.

| Material | Carbon steel | Stainless steel |

|---|---|---|

| Thickness | 0.25mm | 0.25mm |

| 0.3mm | ||

| 0.5mm | ||

| Hardness | HRC52+/-1 | HRC52+/-1 |

| Rust Resistance Ability | *** | ***** |

| Common Size (mm) | 70x140, 75x180, 100x210, 100x200 | |

| 100x215, 100x216, 100x250, 100x260, | ||

| 100x300, 100x350, 100x400, 120x250, 150x300... | ||

| Use For Printers | Apply to all kinds of various Pad Printing Machines Such as TAMPO, | |

| KENT, KINNARI, MORLOCK, CANDOUR, CONVERSE, CONTILOCK, | ||

| MAC, SHARPLINE, SECO & All Indian & Imported etc. | ||